Corrosion Resistant Glass Fiber Composite GRP Angle Profile FRP Pultrusion Profile

Basic Info

| Model NO. | 30mm-150mm |

| Product Categories | FRP Pipe |

| Molding Method | Resin Transfer Molding |

| Material | FRP |

| Fiber Type | GFRP |

| Type | Phenolic FRP |

| Colour | Yellow Red White Blue Gray |

| Resin | Epoxy, Vinyl, Unsaturated |

| Processing Service | Bending, Cutting, Drilling |

| Application | Industry, Construction, Corrosion Environment |

| Technique | Pultrusion |

| Transport Package | Wooden Pallets. Wooden Cases. Containers |

| Specification | customizable |

| Trademark | Ji Xing Xin |

| Origin | China |

| HS Code | 3926909090 |

| Production Capacity | 300, 000 Meters Per Year |

Packaging & Delivery

Package size per unit product 600.00cm * 200.00cm * 180.00cm Gross weight per unit product 1000.000kgProduct Description

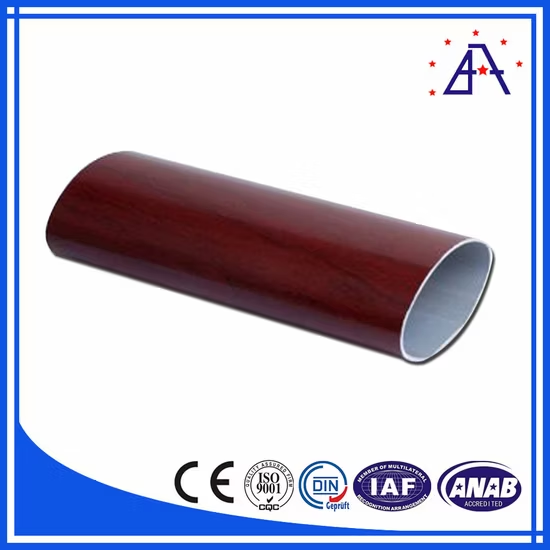

There are many kinds of FRP pultrusion profiles, such as glass fiber reinforced plastic round tube, glass fiber reinforced plastic square tube, glass fiber reinforced plastic rectangular tube, glass fiber reinforced plastic round bar, glass fiber reinforced plastic I-beam. The basic components of pultruded FRP profiles are resin and glass fiber (including cloth, felt, etc.), which is reinforced by fiber (including glass fiber, carbon fiber, organic fiber and other metal, non-metal fiber) and resin (mainly epoxy resin). Polyester resin, phenolic resin) is a binding agent, supplemented by other auxiliary materials (main auxiliary materials: release agent, curing agent, catalyst, sealing agent, UV light stabilizer, mold cleaning water, gelcoat, etc.) composite. It has a series of excellent characteristics such as high temperature resistance, corrosion resistance, high strength, small specific gravity, low moisture absorption, small extension and good insulation. 1. Good dimensional stability The thermosetting ester matrix is crosslinked to form a network structure under the action of heat in the processing process. The product is stable under normal size, and the post-shrinkage after forming is small. Under the action of long time continuous load, the shape and size of the product change very little, that is, the creep is small. Its creep performance depends on the load size, temperature and loading time. The creep variable of thermosetting plastics is much smaller than that of thermoplastics under fixed load and temperature for a long time. 2. Excellent heat and high temperature resistance Thermosetting tree matrix composites can no longer be softened after curing, the heat resistance of its products is quite stable, measured by 1.86MPa load, generally its thermal deformation temperature within 150 ~ 260ºC, and fiber reinforced thermosetting plastics is an excellent insulation material, its thermal conductivity is generally 0.35 ~ 0.47W/ (m.K), Only 1/100 to 1/1000 of the metal can be used as good heat insulation material and instant high temperature resistant material. The thermal deformation temperature of the material can reach 350ºC, which can be used as room temperature and high temperature structural material. Glass fiber/phenolic is an excellent insulation material for rocket and missile engine. 3. Excellent electrical performance Composite material is an excellent electrical insulation material, if the mica as filler to make the product its electrical performance is more excellent, can be used to make arc resistance, voltage resistance, induction electrical properties of superior special parts. Due to the excellent electrical properties of the composite material, its products do not exist electrochemical corrosion and stray current corrosion, can be widely used in the manufacture of instruments, motors and electrical insulation parts, in order to improve the reliability of electrical equipment and prolong its service life. In addition, the products have good dielectric properties and microwave transmission under the action of high frequency, and have been used in the manufacture of a variety of high frequency insulation products such as radomes. 4. Excellent corrosion resistance The electrochemical corrosion mechanism of tree ester based composite material is different from that of ordinary steel. It does not conduct electricity and will not dissolve ions in the dielectric solution, so it has good chemical stability to the atmosphere, water and the general concentration of acid, base, salt and other media, especially in the non-oxidizing strong acid and a wide range of ph values of the medium. Therefore, widely used in the manufacture of corrosion resistant products, for stainless steel can not deal with some media (such as hydrochloric acid, chlorine gas, carbon dioxide, dilute sulfuric acid, sodium hypochlorite and sulfur dioxide, etc.) corrosion, has played a good role. 5. Good surface characteristics of FRP pultrusion profiles The surface of composite materials and chemical media contact with very little corrosion, and very little scaling, so commonly used in the manufacture of fluid pipeline, the pipeline resistance is small, low friction coefficient, saving a lot of power. This is why composite products are widely used in the food and pharmaceutical industries because they are generally less prone to producing metal ion contamination media than metals. In addition, the composite material has a high pv limit value. Under the condition of water lubrication, its friction coefficient is very small, about 0.01 ~ 0.03, so it is also the preferred material for wear-resistant products. |

Detailed Photos

Q: Are you a trading company or a manufacturing plant?

We are an export qualified manufacturing plant. Our factory is one of the best manufacturers of FRP products in China

Q: Do you provide samples? Is it free or extra?

Yes, we can provide some samples free of charge, but we don't pay for shipping.

Please contact me for confirmation.

Q: What is your lead time?

a: Usually 5-10 days if they are available. It depends on the product. Check with me.

Q: Does your factory offer customized services?

Yes, we can. We can provide most kinds of custom service from small parts to large machines.

Q: Is it possible to contract?

Yes, we can provide OEM and ODM. What are your payment terms?

Usually by wire transfer, letter of credit, paypal, Western Union also works. 30% telegraphic transfer in advance, balance paid before shipment timely and professionally reply to your enquiry

Normally we will reply to you by email within 5-8 hours, 24 hours is plenty considering the time difference!